The engineers at Satie North America believe that leveraging advanced technology is the solution to providing cost-effective, high-quality products that deliver reliable, efficient performance.

That’s why we’ve adopted CNC (Computer Numerical Control) technology to help our customers save time and money with superior wiring management frames built to their exact specifications.

What Is CNC manufacturing?

CNC is part of the latest wave of manufacturing innovations that help streamline and shorten the production process.

This advanced method of manufacturing is driven by numerical code generated by its software. The code is typically based on a 2D or 3D design concept, usually created using a CAD (Computer-Aided Design) program.

The code is translated into a series of detailed instructions that control the various types of fabrication equipment, automating processes such as milling, cutting, grinding, and more. Some CNC machines include automated turning functionality that adjusts the position of the workpiece for additional processing.

What Satie’s CNC Technology Means For Our Customers

Believe it or not, machinists once had to review paper-based drawings, take manual measurements, and painstakingly build the part with manual tools.

Although this process worked for centuries, we’re fortunate to live in an age where manufacturing, such as CNC machining, makes production faster, more accurate, and with enhanced quality while mitigating the risk of human error.

At Satie, our CNC manufacturing technology has almost unlimited potential to impact our production capabilities positively. Here are just a few of the ways our customers benefit from CNC manufacturing:

Enhanced Fabrication Accuracy Of Complex Projects

Regardless of the complexity of your wiring frame project, CNC technology allows our engineers to easily navigate custom designs with absolute precision. No detail is missed during fabrication, including deep, narrow pockets, complex or nonlinear surface geometries and patterns, tight tolerances, undercuts, unique aspect ratios, and much more.

This flexibility means that our team can create virtually any design, no matter how large or complex.

Fast, Simple Design Adjustments Before, During, Or After Production

At Satie, our engineers work closely with our customers to learn all about their needs and the specific product configuration they require. We then use CAD software to create detailed drawings for their approval.

Adjustments to the design are easy because the system stores the approved designs in case repeat orders are required. However, if any changes need to be made to the original design as companies grow, their needs change, or they need to optimize their space, there’s no need to go back to the drawing board or start over from scratch.

Whether switching to a different source material, adding additional rails, changing dimensions, or making any other change, a quick editing session is all it takes to redesign the component before going into production again.

Read More: Our Process

Faster Delivery Time

Staying competitive is critical to any business’s success. When you need a new wiring management system to keep production moving and stay ahead of the competition, you need fast results that still prioritize quality.

CNC-based processes can be partially or fully automated, significantly reducing production time because computers don’t need to take breaks. Fabrication can run around the clock, enabling us to deliver our products to customers faster, providing them with a profit-boosting competitive edge.

Improved Tool Maintenance

Sometimes, during the manufacturing process, cutting tools can wear down or break. This often means stopping production suddenly so the tool can be replaced, which can be costly in terms of machine downtime, lost productivity, and later delivery.

However, CNC technology can make unplanned work stoppages due to tool failure a thing of the past. CNC manufacturing systems are often integrated with

sensors and real-time tool monitoring systems that can detect and report potential tool wear and tear long before there’s a risk of breakdown. This feature reduces the risk of delayed production and helps ensure that manufacturing can continue moving forward on time.

Partner With Satie For High-Quality Products Built With Advanced Technology

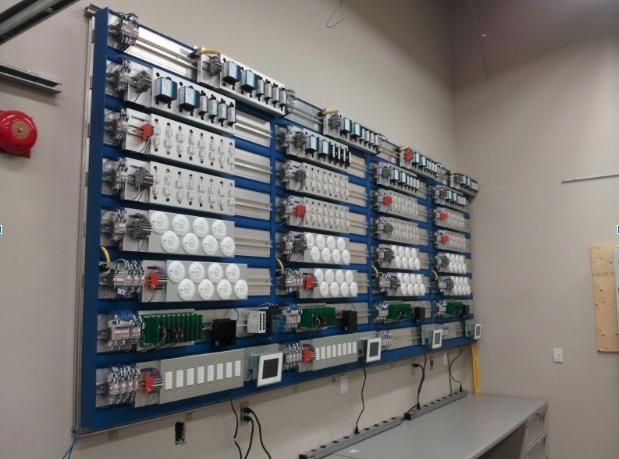

Satie engineers have the skills, tools, and technology to design and fabricate high-quality wiring management frames built to your exact specifications. Our frames are built to provide decades of reliable service and can be installed in minutes without the need for drilling or tapping.

It’s simply the best, most cost-effective wiring management solution on the market today. Learn more about the benefits of a customized wiring management frame solution by giving the experts at Satie a call today!

Read More: What Fast Growing Manufacturers Know About Efficient Electrical Panel Framing

Contact A Satie Expert Today For A Control Panel Frame Solution Tailored For Your Specific Needs

Make it easy – make it Satie! We are North America’s premier choice for high-quality electrical control panel frames designed to last for decades. Call (647) 477-2433 or visit www.satiena.com/contact today for more information on how our products can help you reach your organizational goals.