As we turn the calendar to another year, many companies across the industrial spectrum will be looking at ways to cut costs in 2026 in order to help boost sustainable profits.

One of the most underestimated costs in today’s production environments is the continued use of outdated wiring management systems, which drain revenue through unexpected downtime, inefficiencies, and rework when something needs maintenance, replacement, or repair.

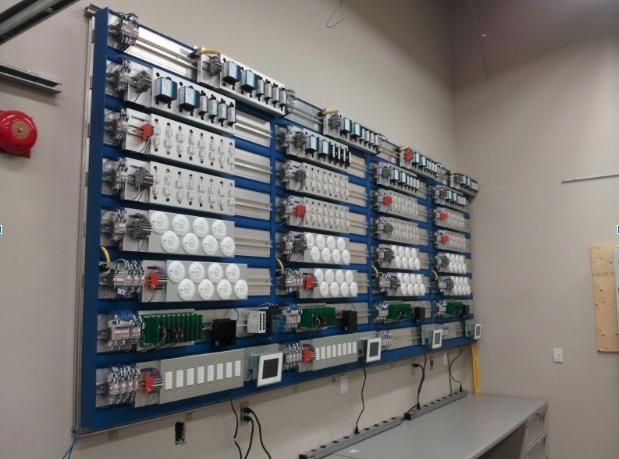

The truth is that companies can save money by investing in an updated wiring management panel. Upgraded panels directly influence the performance, lifecycle, and maintainability of every downstream component within an enclosure, providing measurable financial returns over the long term.

Here are five ways that upgraded wiring management panels provide a solid return on investment that boosts profits.

Virtually Limitless Scalability

Most legacy wiring management systems weren’t designed for the complexity of today’s panels. As your business grows, your panel infrastructure will need to support higher circuit density, placing new demands on routing pathways and structural support inside the enclosure. Legacy frames that aren’t rigid, modular, or adaptable enough for scalability lead to increased costs such as extra labour hours, maintenance cycles, inventory waste, and unplanned downtime.

That’s because your technical teams will spend more time trying to modify frames that weren’t designed to accommodate additional loads or cleaner separation. This can also lead to disorganized wiring and cluttered, overfilled pathways, creating excessive heat pockets or mechanical stress and increasing the risk of sudden component failure.

Upgraded wiring management frames are built for scalability, enabling your team to add new components without compromising your current configurations or wiring organization. Innovations won’t wait for companies to upgrade their systems, so the sooner companies replace their existing panels with ones built for the future, the better their long-term ROI will be.

Less Time Spent Adding Components

One of the easiest costs to measure is labour productivity, which is enhanced when adding new components to your wiring management panel. Modern frame designs feature consistent mounting patterns and clean routing channels, enabling teams to complete additions faster and with fewer errors, and allowing them to move more efficiently from one enclosure to the next.

Integrating a standardized wiring infrastructure with modern panels reduces the engineering hours required to plan variations, minimizes the learning curve for new technicians, and accelerates assembly cycles.

For business owners, this translates to lower labour cost per panel and the ability to redirect engineering personnel toward value-added tasks rather than wrestling with outdated equipment.

Reduced Downtime Through Easier Troubleshooting

In high-demand production environments, every minute of downtime has a direct financial impact. Technicians must be able to open a panel, locate the problem, and take corrective action without navigating a maze of disorganized wiring.

Modern panels are created with wire paths that improve visibility and accessibility into the enclosure. This helps reduce the hours your team spends troubleshooting and maintaining your panels, while lowering the likelihood of accidental disturbances caused by disorganized wiring systems on older panels.

The innovative frame designs available today help save hours of maintenance, resulting in tangible savings in labour costs.

Read More: 5 Signs Your Control Panels Need A Frame System Upgrade

Increased Component Longevity Through Better Heat Management

One aspect of many problems associated with legacy panels is poorly designed wiring routing that restricts airflow and increases operating temperatures inside the enclosure.

Elevated temperatures accelerate insulation fatigue, reduce conductor lifespan, and place stress on sensitive electronics, leading to system maintenance or parts replacement.

However, upgraded wiring management frames features improved wiring organization that’s securely supported, improving airflow and allowing components to operate closer to their intended thermal range. Even slight reductions in temperature can dramatically extend the lifespan of drives, PLCs, contactors, and power supplies.

Modern panels are also built with materials known for their thermal conductivity, which helps dissipate heat more evenly and complements the panel’s cooling strategy.

Longer-lasting components translate directly into fewer replacements, less downtime, and more predictable maintenance budgets. Over the lifecycle of a control panel, the savings often outweigh the initial upgrade cost.

Supports Emerging Technology

As manufacturers embrace Industry 4.0 technology, panels are becoming increasingly complex. New communication networks, sensors, and smart components require more disciplined cable routing and greater separation between power and data wiring. Legacy frames, built in an era before this technology existed, often become barriers to modernization.

Advanced wiring management frame designs feature modular architecture that supports reconfiguration for new technology without compromising structural integrity. Your technical teams can easily integrate new devices, reroute existing wiring, or expand PLC racks without the cascading disruption associated with older frame designs.

Companies will also discover that the cost of retrofitting an outdated frame several years from now will exceed the cost of choosing a modern frame system today, boosting short-term profits.

Read More: The Satie Advantage

Partner With Satie For High-Quality Products From A Trusted Partner

At Satie North America, our wiring management frames are built with innovative, forward-thinking designs that will help your company increase profits through sustainable ROI.

As the only company in the world dedicated exclusively to designing and manufacturing custom wiring management frames, we are committed to delivering high-quality products precision-built using CNC technology. Satie frames are built to provide decades of reliable service, can be installed in minutes without drilling or tapping, and offer a cost-effective solution developed solely to support your business needs.

Learn more about the benefits of a customized wiring management frame solution by giving the experts at Satie a call today!

Contact a Satie expert today for a control panel frame solution tailored for your specific needs

Make it easy – make it Satie! We are North America’s premier choice for high-quality electrical control panel frames designed to last for decades. Call (647) 477-2433 or visit www.satiena.com/contact today to learn how our products can help you achieve your organizational goals.